Call us now

08045802359Carbide Grinding Wheels

550 INR/Piece

Minimum Order Quantity : 100 Pieces

Delivery Time : 2-3 Days

Supply Ability 100 Per Day

About this product

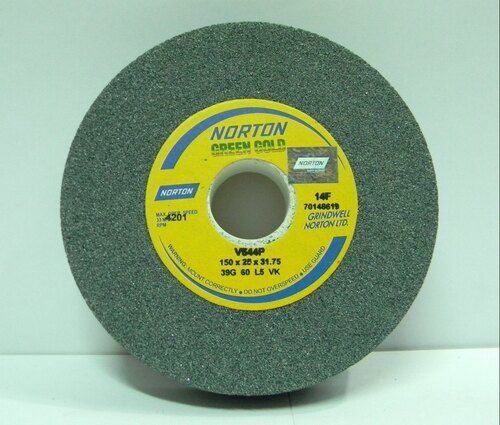

Carbide Grinding Wheels

Centerless Grinding Wheel

2100 INR/Piece

Minimum Order Quantity : 10 Pieces

Delivery Time : 10 Days

Type Centerless Grinding Wheel

Toughness High fracture resistance

Strips Size Conforms to application requirement and wheel diameter

Shape Straight, cylindrical

Rolls Size Standard dimensions as per industry norms; customizable on request

Material High-grade aluminum oxide or silicon carbide

Hardness Medium to hard

Grain Type Aluminum oxide or silicon carbide

Grain Sizes Available from fine to coarse; typically ranged between 24 to 120 grit

Chemical Composition Al2O3 (Aluminum Oxide) or SiC (Silicon Carbide) as main component

Bonding Resinoid, vitrified, or rubber

Backing No backing required; full dense wheel

Supply Ability 100 Per Day

About this product

A Versatile Precision Tool for Industrial Applications

Centerless Grinding Wheels are extensively used for precision grinding of cylindrical components such as bars, rods, and automotive parts. Suitable for industrial, heavy-duty, and continuous-usage scenarios, they also find applications in tool manufacturing, metalworking, and finishing tasks across a spectrum of industries. With adjustable grain sizes and dimensions, these wheels easily adapt for both general and specialized grinding operations, delivering optimal accuracy and superior surface finish every time.

Swift Delivery and Professional Dispatching Process

Centerless Grinding Wheels are packed securely to ensure product integrity during shipment. We typically dispatch orders within a short lead time depending on customization. Our FOB Port is located in India, facilitating efficient domestic and international logistics. Samples can be provided as per our sample policy, with nominal charges applicable. Each package is designed for safety to prevent damage, ensuring that your orders reach you in pristine condition, ready for immediate use upon arrival.

FAQ's of Centerless Grinding Wheel:

Q: How do I select the most suitable grit size for my grinding application?

A: Choosing the right grit depends on your surface finish requirements and material hardness. Finer grits (e.g., 120) yield smoother finishes, while coarser grits (e.g., 24) enable robust stock removal for tougher materials. Our team can guide you based on your process needs.Q: What benefits do Centerless Grinding Wheels offer for precision machining?

A: These wheels deliver high-accuracy surface finishes below 0.2 m Ra, potent material removal rates, and reduced setup times. Their top-tier material construction ensures repeatable performance and durability, making them a masterpiece for industrial productivity.Q: Where are these grinding wheels manufactured and shipped from?

A: All Centerless Grinding Wheels are manufactured conforming to ISO and DIN standards in India. Shipments are dispatched from our Indian FOB port, with secure packaging for both domestic and international delivery.Q: What is the typical delivery time after placing an order?

A: Delivery times can vary based on order volume and customization requests. Standard items are generally dispatched promptly, while custom specifications may require a few additional days. We prioritize prompt dispatch to minimize your wait.Q: Can these wheels handle both wet and dry grinding operations?

A: Yes, the design supports both wet and dry grinding methods, broadening their usability and making them adaptable for varied operational environments.Yuri Flap Disc

21 INR/Piece

Minimum Order Quantity : 100 Pieces

Delivery Time : 2-3 Days

Type Yuri Flap Disc

Size 100x16 mm

Shape Round

Product Type Yuri Flap Disc

Color Black

Supply Ability 1000 Per Day

About this product

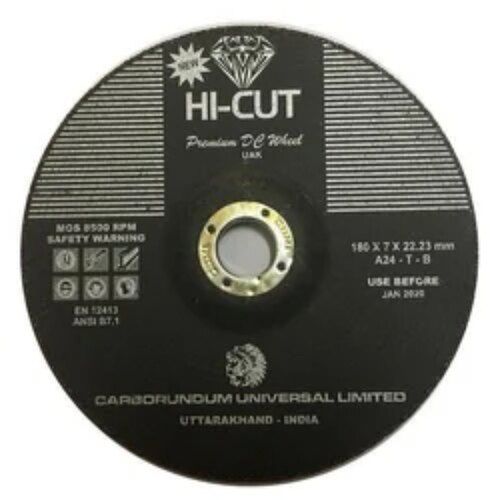

CUMI Cutting Abrasives

10 INR/Number

Minimum Order Quantity : 100 Number

Delivery Time : 2-3 Days

Type Cutting Abrasive

Toughness High

Strips Size 25 mm x 1 m

Shape Rolls & Strips

Rolls Size 100 mm x 50 m

Material Aluminum Oxide

Hardness Medium to Hard

Grain Type Brown Fused Alumina

Grain Sizes 36, 40, 60, 80, 100

Chemical Composition Al2O3 with minor additives

Bonding Resin

Backing Flexible Cloth

Supply Ability 100 Per Day

About this product

Outstanding Versatility for Industrial Use

CUMI Cutting Abrasives are engineered for medium to hard metal cutting and industrial fabrication. The brown color and aluminum oxide material, available in multiple grain sizes (36, 40, 60, 80, 100), ensure excellent cutting efficiency. With its flexible cloth backing, these abrasives are ideal for surface preparation, foundry cleaning, and heavy engineering. Uniform granule distribution and high toughness further enhance performance, making these tools suitable for demanding, repetitive usage.

Certifications, Packaging, and Secure Shipping

CUMI Cutting Abrasives comply with industry certifications, ensuring reliability and quality for every shipment. Packaging is designed to protect products during transportation, with robust materials guaranteeing shipped goods arrive in optimal condition. Secure shipping processes minimize risk of damage, while sample policies allow evaluation prior to bulk purchase. Whether distributor, importer, supplier, or trader, buyers across India can expect consistently safe delivery and professional handling with every order.

FAQ's of CUMI Cutting Abrasives:

Q: How can CUMI Cutting Abrasives enhance my industrial cutting processes?

A: CUMI Cutting Abrasives are crafted using high toughness brown fused alumina, providing stable and efficient cutting for metals and heavy engineering. Uniform grain distribution and medium to hard hardness ensure consistent results and longer abrasive life.Q: What types of surfaces or materials are suitable for CUMI Cutting Abrasives?

A: These abrasives are ideal for cutting and processing a range of metals and are particularly effective in fabrication, foundry, and heavy engineering applications due to their chemical composition and resilience.Q: When should I consider replacing CUMI Cutting Abrasives?

A: You should replace the abrasives when you notice a decline in cutting efficiency, visible wear, or reduction in product thickness. These signs indicate the abrasive has reached the end of its optimal lifespan.Q: Where can CUMI Cutting Abrasives be purchased in India?

A: CUMI Cutting Abrasives are available through authorized distributors, importers, suppliers, and traders throughout India. Connect with your local industrial supplier or CUMI dealer for stock and pricing.Q: What packaging and shipping measures are in place to protect shipped goods?

A: Every order is securely packaged with durable materials to prevent damage during transportation. The shipping process is designed to ensure goods arrive safely and intact, maintaining the abrasives' superior quality.Q: How can I request a sample before bulk purchasing CUMI Cutting Abrasives?

A: Sample policies are available; you can request samples through official distributors or suppliers to evaluate the abrasives' suitability for your specific applications before committing to bulk orders.Abrasive Cut-Off Wheels

9 INR/Piece

Minimum Order Quantity : 100 Pieces

Delivery Time : 2-3 Week

Type Abrasive Cut-Off Wheel

Toughness High fracture toughness for heavy-duty cutting

Shape Flat, Depressed Center

Rolls Size Available in 355 mm, 400 mm, 450 mm, 500 mm, 600 mm diameter

Material Aluminum Oxide, Silicon Carbide

Hardness Medium to Hard

Grain Type A (Aluminum Oxide), C (Silicon Carbide)

Grain Sizes 16, 24, 30, 36, 46

Chemical Composition Al2O3, SiC, Phenolic Resin

Bonding Resinoid Bond

Backing Fiber Reinforced

Supply Ability 100 Per Day

About this product

Versatile Usage & Wide Applications

Our Abrasive Cut-Off Wheels are used for precision cutting of steel, stainless steel, cast iron, and non-ferrous metals. Perfectly suitable for industrial cutting and metal fabrication, they find application in workshops, factories, and construction sites. Whether it's heavy-duty fabrication or routine maintenance work, these wheels deliver clean, smooth cuts with unparalleled efficiency. Available in both flat and depressed center shapes, they adapt to various machines and cutting requirements, making them an indispensable tool for professionals.

Sample Policy & Domestic Supply Ability

We offer flexible sample policies-contact us for details on sample availability at list price. Serving the entire domestic market, our distribution network ensures rapid delivery anywhere in India. With a robust supply ability, we efficiently process large purchase orders for ongoing projects or bulk demands. Guaranteed integrity and reliable packaging ensure products arrive in immaculate condition every time you order. Trust us as your preferred partner for all industrial cutting needs across the domestic mar.

FAQ's of Abrasive Cut-Off Wheels:

Q: How do I select the right abrasive cut-off wheel for my material and application?

A: Choose a wheel based on material type, thickness (2-4 mm), and diameter (355-600 mm). For steel or stainless steel, opt for Aluminum Oxide; for non-ferrous or cast iron, Silicon Carbide is preferred. Ensure compatibility with your machine's maximum RPM and center hole diameter.Q: What benefits do these abrasive wheels offer for industrial cutting tasks?

A: These wheels deliver smooth, burr-free cuts with high fracture toughness and immaculate finish, even in heavy-duty environments. Their reinforced, heat-resistant build ensures safety during high-speed operations, prolonging both tool and user safety.Q: Where can these cut-off wheels be used?

A: They are suited for use in workshops, metal fabrication shops, construction sites, and various industrial settings where steel, stainless steel, or cast iron cutting is regularly performed.Q: What is the process for placing a purchase order or requesting a sample?

A: Simply contact us with your requirements to receive a list price quote. Upon confirmation, submit your purchase order for bulk or sample delivery, and benefit from our instant checkout and reliable domestic mar supply chain.Q: When should I replace my abrasive cut-off wheel?

A: Replace your cut-off wheel when you notice excessive wear, reduced cutting efficiency, or visible cracks and damage. Always follow manufacturer guidelines for best results and safety.Abrasive Wheels

10 INR/Piece

Minimum Order Quantity : 100 Pieces

Delivery Time : 1 Days

Supply Ability 100 Per Day

About this product

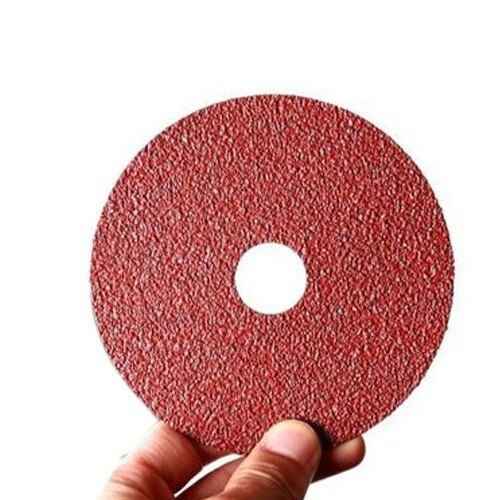

Abrasive Discs

10 INR/Piece

Minimum Order Quantity : 100 Pieces

Delivery Time : 01 Days

Supply Ability 100 Per Day

About this product

Coated Abrasive Wheels

500 INR/Piece

Minimum Order Quantity : 100 Pieces

Delivery Time : 2-3 Days

Usage Industrial

Size Different Available

Shape Round

Product Type Coated Abrasive Wheels

Color Black

Supply Ability 1000 Per Day

About this product

Buffing Wheels

30 INR/Piece

Minimum Order Quantity : 100 Pieces

Delivery Time : 2-3 Days

Type Stitched, Loose, Bias, Treated, and Sisal Wheels

Toughness High

Strips Size Customized as per requirement

Shape Round / Disc

Rolls Size 8, 10, 12, 14, 16, 18, 20 Inch

Material Cotton / Wool / Sisal / Felt

Hardness Soft, Medium, Hard (as per cotton ply or material)

Grain Type Alumina, Silicon Carbide, or None (for plain cotton)

Grain Sizes Fine, Medium, Coarse

Chemical Composition Varies as per base fabric and impregnation

Bonding Stitched, Glued or Resin Bonded

Backing Multiple fabric layers or felt

Supply Ability 100 Per Day

About this product

Commercial Buffing Wheels: Professional Uses and Versatile Features

Buffing wheels are essential for a wide range of commercial applications, including polishing, buffing, and surface finishing of metals, plastics, and wood. Suitable for distributors, suppliers, traders, and importers across India, these wheels offer exceptional performance for workshops, factories, and industrial plants. With features like multiple bonding options, varying hardness, and customizable strip sizes, users can achieve polished, smooth, and professional surfaces on almost any compatible machine. Available in round or disc shapes to fit diverse requirements.

Supply Ability, Certifications, and Efficient Delivery of Buffing Wheels

Our supply chain ensures steady availability of buffing wheels with order completion and quick dispatch for every purchase. Accredited quality certifications assure reliability and consistency, maintaining competitive list prices for bulk and retail orders. Delivery time is optimized through instant checkout and streamlined logistics, enabling customers to receive their orders promptly anywhere in India. Custom packaging, in either boxes or bags, adds an extra layer of convenience for traders, importers, and suppliers looking to minimize downtime.

FAQs of Buffing Wheels:

Q: How can I personalise my Buffing Wheel order to match my specific requirements?

A: You can personalise your Buffing Wheel order by selecting the desired color, grain size, material (cotton, wool, sisal, or felt), thickness, shape, and bonding type. Custom strip sizes and center hole diameters from 16 mm to 50 mm are available for specialised applications.Q: What machines are compatible with your Buffing Wheels?

A: Our Buffing Wheels are compatible with bench grinders, hand polishers, and angle grinders, providing flexibility for various industrial and commercial uses.Q: When will I receive my Buffing Wheels after placing an order?

A: Orders are processed swiftly, with quick dispatch and efficient shipping. Delivery time will generally depend on your location in India, but most customers receive their wheels within a few business days after order completion.Q: Where are these Buffing Wheels supplied?

A: We supply Buffing Wheels across India, catering to distributors, traders, suppliers, and importers in all major regions, with reliable logistics and packaging options.Q: What is the process for selecting the right Buffing Wheel for different surface finishing tasks?

A: To select the right Buffing Wheel, assess the material to be polished, desired finish, hardness (soft, medium, hard), and compatible grain type (alumina, silicon carbide, or none). We offer expert guidance to ensure you choose the wheel that delivers the best results for your application.Q: What are the benefits of using your Buffing Wheels?

A: Our Buffing Wheels provide superior surface finishing, heat resistance up to 120C, exceptional toughness, and versatility in commercial settings. They are designed for durability and consistent performance while being available in custom sizes and multiple bonding types.Explore Additional Categories

Contact Us

Our Products

Our Products